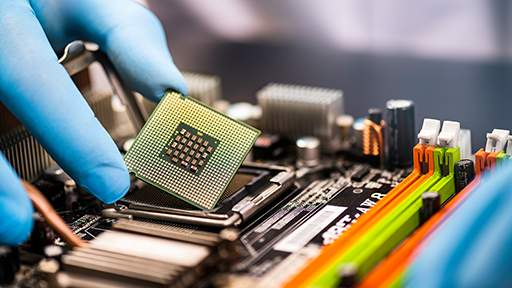

A semiconductor test system is a specialized piece of equipment used to test the performance and functionality of semiconductor devices. These systems typically consist of a test head that makes physical contact with the device being tested and a test controller that controls the head and manages the process.

The systems are used in a variety of settings, including research and development laboratories, manufacturing facilities, and quality assurance departments. They are an essential tool for ensuring the performance and reliability of devices, and they are used in a wide range of industries, including consumer electronics, automotive, aerospace, and telecommunications. Some of the main advantages include the following.

Advantages of the semiconductor test system

Improved accuracy

The testing environment is designed to be highly accurate and precise, allowing for detailed and reliable testing of devices. They produce a minimum count of error which helps to attain accurate results. This testing is particularly important in applications such as in the aerospace or automotive industries which require highly precise measurements.

Enhanced efficiency and speed

Semiconductor test systems are able to test devices quickly and efficiently, which can help to reduce the time and cost associated with testing. This is particularly important in high-volume manufacturing environments, where large numbers of devices need to be tested on a regular basis. This allows operators to test more number of devices, increasing its efficiency and effectiveness.

Enhanced flexibility and adaptability

Many semiconductor test systems are highly flexible and adaptable to meet the specific needs of the devices being tested. This allows manufacturers to test a wide range of devices with a single system, which can be more cost-effective than purchasing multiple systems for different types of devices.

Improved reliability and consistency

They are designed to be consistent, which is important for ensuring the performance and quality of devices. Automation is capable of detecting minute defects that could lead to potential risks in usage and suggest improvements. This contributes to making them more reliable for users in practical world.

Enhanced data analysis and reporting capabilities

Many of these systems come with advanced data analysis and reporting capabilities, which can help manufacturers analyze and understand their tests’ results. This can be particularly useful for identifying problems or defects in devices and for making improvements to the manufacturing process.

Improved safety

ATE semiconductor testing is particularly important in manufacturing environments where there may be hazards present. Moreover, testing the devices makes the manufacturer well aware of their limitations and makes necessary adjustments to ensure more safety. They also come to know about practical working load, which helps them enhance their life span.

Enhanced environmental sustainability

A majority of such systems are designed to be energy-efficient and environmentally friendly, which can help manufacturers reduce their carbon footprint and minimize their environmental impact. They conduct multiple tests which reduce the utilization of energy and cut short sustainable alternatives.

Increased customer satisfaction

Manufacturers can increase customer satisfaction and loyalty by producing high-quality devices that meet performance and functionality requirements. Users also develop trust in their part when they see certifications and get assured of the quality.

Enhanced competitiveness

Manufacturers can increase their competitiveness in the market by using semiconductor test systems to optimize the manufacturing process and produce high-quality devices. This makes them more efficient and is likely to earn more revenue.

Conclusion

Overall, the uses of semiconductor test systems provide many benefits for manufacturers, including improved accuracy and precision, enhanced efficiency and speed, improved reliability and consistency, and enhanced data analysis and reporting capabilities. These systems are essential for ensuring the performance and quality of semiconductor devices and are used in many industries and applications.